This year we have a strong opening of the EFDS ALD for Industry with Prof. Kessels giving the Keynote follwoing up with strong opresenattions form Infineon, Picosun, Veeco, IHP, Euris/Arradiance and Air Liquide. (LINK)

↧

Strong opening of the EFDS ALD for Industry in Berlin

↧

Critical Materials Business and Technology Information 2019

4th Annual Critical Materials Council (CMC) Conference April 25-26 in Saratoga Springs, New York a must-attend for business and technology professionals concerned with global supply-chains for semiconductor manufacturing.

TECHCET will host the 4th annual Critical Materials Council (CMC) Conference April 25-26 at the Saratoga Hotel and Casino in Saratoga Springs, New York. At the CMC Conference, business visionaries and manufacturing technologists gather to address current and future materials challenges. The latest forecasts on market drivers including trade issues, along with technical issues facing the global materials supply-chain, will be shown.

TECHCET will host the 4th annual Critical Materials Council (CMC) Conference April 25-26 at the Saratoga Hotel and Casino in Saratoga Springs, New York. At the CMC Conference, business visionaries and manufacturing technologists gather to address current and future materials challenges. The latest forecasts on market drivers including trade issues, along with technical issues facing the global materials supply-chain, will be shown.

The public CMC Conference follows private CMC face-to-face meetings to be held April 23-24, 2019 at GlobalFoundries in Malta, New York. Themes are centered around the needs of the Critical Materials Council and the global IC fabrication industry. While executive conferences typically focus on the "what" and "why" of materials technologies, this conference will discuss "how" new materials can be controllably, safely, and cost-effectively used in fabs.

The CMC Conference this year will feature a keynote presentation on "International Supply-Chain Management Challenges," by Dr. John Pellerin, Deputy CTO and VP of Worldwide R&D of GlobalFoundries.

Other featured presentations include:

The CMC Conference this year will feature a keynote presentation on "International Supply-Chain Management Challenges," by Dr. John Pellerin, Deputy CTO and VP of Worldwide R&D of GlobalFoundries.

Other featured presentations include:

- Tim Yeakley, ESH Policy Manager, Texas Instruments, on "Global Materials Regulation Issues,"

- Dr. Karl Robinson, Director of Process Engineering, IMEC, on "Materials Engineering in CMOS and Beyond-CMOS Applications,"

- Dr. Bryan Rice, VP of Product Integration, Inpria Corp., on "EUV Photolithography Materials Integration,"

- G. Dan Hutcheson, CEO, VLSI Research, on "Slowdown: When did it start? What drove it? and When will the recovery come?" and

- Gus Richard, Managing Director, Northland Securities, on "Macroeconomics & Drivers Influencing the Electronics Industry."

Register now at the early-bird rate of just $395: https://cmcfabs.org/cmc-events/

ABOUT CMC: The Critical Materials Council (CMC) of Semiconductor Fabricators (CMCFabs.org) is a membership-based organization that works to anticipate and solve critical materials issues in a pre-competitive environment. The CMC is a business unit of TECHCET, and includes materials supplier Associate Members.

ABOUT TECHCET: TECHCET CA LLC is an advisory services firm focused on process materials supply-chains, electronic materials business, and materials market analysis for the semiconductor, display, solar/PV, and LED industries. Since 2000, the company has been responsible for producing the SEMATECH Critical Material Reports™, covering silicon wafers, semiconductor gases, wet chemicals, CMP consumables, Photoresists, and ALD/CVD Precursors. For additional information about reports, market briefings, CMC membership, or custom consulting please contact info@cmcfabs.org, +1-480-332-8336, or go to http://www.techcet.com or http://www.cmcfabs.org.

↧

↧

NCD Contracted with Risen Energy to supply 1.6GW solar cell ALD equipment

NCD recently signed the largest contract with Risen Energy, a Chinese solar cell manufacturer, to provide 1.6 GW solar cell manufacturing equipment in the next six months. This is a repeat order following the last purchase, so it indicates that the superiority and reliability of NCD’s ALD equipment has been fully proven to the customer.

This system is Lucida GS Series with Automation, the main product of NCD's solar division. By applying Lucida GS Series in the production of solar cells, customers chan dramatically lower the production cost of high efficiency solar cells due to the high-volume productivity, high yield, efficient gas consumption and low maintenance cost compared to competitors.

NCD will have continually made efforts to help our customers successful together and to become the world’s best ALD technology specialized company.

This system is Lucida GS Series with Automation, the main product of NCD's solar division. By applying Lucida GS Series in the production of solar cells, customers chan dramatically lower the production cost of high efficiency solar cells due to the high-volume productivity, high yield, efficient gas consumption and low maintenance cost compared to competitors.

NCD will have continually made efforts to help our customers successful together and to become the world’s best ALD technology specialized company.

(Lucida GS Series + Automation)

↧

Strem Chemicals offers ALD & CVD Precursor bubblers and ampoules for R&D and high volume manufacturing

Strem Chemicals, Inc. manufactures and markets specialty chemicals of high purity. Their products are used for research and development, as well as commercial scale applications, especially in the pharmaceutical, microelectronic and chemical/petrochemical industries.

Strem Chemicals has more than fifty years of experience in manufacturing inorganic and organometallic chemicals and probably the world´s most extensive product offering of MOCVD, CVD, and ALD precursors. Continually adding new products for this dynamic and exciting field, their range of products is presented in the on-line catalog (LINK) and include:

- Metal alkyls

- Metal alkylamides and alkylimides

- Metal amidinates

- Metal alkoxides

- Metal β-diketonates

- Metal cyclopentadienyls

- Metal halides

- Volatile organometallics

- Volatile metal carbonyls

- Fluorinated derivatives

- Electronic grade chemicals

- Single source precursors for mixed metal oxides

The standard and absolutely safest way to transport and deliver highly reactive ALD & CVD precursors is in stainless steel ampoules. These are often referred to as bubblers since in many cases they are fitted with a dip tube on the inlet allowing efficient vapor delivery by an inert carrier gas like N2, He or Ar. These bubblers are readily fitted with seal tight valves and VCR vacuum fittings for easy and safe installation directly on the ALD/CVD tool gas box by a qualified person.

In addition to their 450+ precursors, Strem Chemicals offer a variety of electropolished stainless steel bubblers at capacities ranging from 150ml to 3000ml. These bubblers are available in horizontal-in-line and vertical configurations. While standard bubblers are equipped with diaphragm valves rated to 121°C (PCTFE stem tips), Strem also supplies bubblers with high temperature bellows valves rated to 315°C. DOT and UN approved configurations are available.

In addition to their 450+ precursors, Strem Chemicals offer a variety of electropolished stainless steel bubblers at capacities ranging from 150ml to 3000ml. These bubblers are available in horizontal-in-line and vertical configurations. While standard bubblers are equipped with diaphragm valves rated to 121°C (PCTFE stem tips), Strem also supplies bubblers with high temperature bellows valves rated to 315°C. DOT and UN approved configurations are available.

An assortment of cylinders for ALD can be found in the on-line catalog (LINK) with standard, high-temperature and high-purity options. In addition, Strem Chemicals provides additional services to our customers for their MOCVD, CVD & ALD needs such as:

- Cylinder/Bubbler Cleaning

- Precursor Filling & Refilling

- Prepackaged Precursors in ALD Cylinders

Above, are small sized vapor draw ampoules for research amounts of precursors. The sleek design affords a very compact precursor delivery system.

Bubbler specifications

Strem Chemicals allows you to match a bubbler to your current ALD or CVD tool gas box. The bubbler can be specified using a vast range of types, dimensions and valve configurations. Depending on the precursor to be supplied the valves, materials and dip tube configuration can be optimized for the most efficient precursor delivery even at elevated temperatures (up to 315 °C).Strem offers four of the most popular bubbler designs, and can be made to fit inside most of the ALD/CVD tools on the market today as well many custom build systems.

Once you decide your preference of bubbler, you will need to measure the critical dimensions (A to E), such as volume, temperature operation and dip tube configuration. Then you´re ready to order the ideal bubbler filled with your desired precursor. By following the guide you can be sure that the bubbler will fit like a glove into your precursor cabinet!

Example of a bubbler configuration sheet for a stainless steel bubbler fitted with high temperature valves.

↧

Picosun’s ALD encapsulation prevents electronics degradation

ESPOO, Finland, 14th February 2019 (LINK) – Picosun Group, a leading supplier of ALD (Atomic Layer Deposition) thin film coating solutions for global industries, reports unprecedented results in high reliability electronics protection with ALD.

Hermetic encapsulation by ALD nanolaminates developed by Picosun has been proven to block tin whisker formation on PCB (printed circuit board) assemblies completely(*). During the observation period of over one month to three years, ALD-protected samples showed no tin whisker growth at all, whereas on non-protected samples tin whisker density of over 1000 pcs/cm2 was measured. In addition to blocking tin whiskering, Picosun’s ALD nanolaminates help to protect the PCBAs against other key degradation phenomena such as various forms of corrosion and oxidation. Hermetic ALD coating works efficiently even against moisture and gaseous sulfur in polluted atmosphere. Due to its nanometer-scale thickness, the ALD film has no effect on the PCBA functionality, mass or dimensions and it allows reworking of the PCBA.

Hermetic encapsulation by ALD nanolaminates developed by Picosun has been proven to block tin whisker formation on PCB (printed circuit board) assemblies completely(*). During the observation period of over one month to three years, ALD-protected samples showed no tin whisker growth at all, whereas on non-protected samples tin whisker density of over 1000 pcs/cm2 was measured. In addition to blocking tin whiskering, Picosun’s ALD nanolaminates help to protect the PCBAs against other key degradation phenomena such as various forms of corrosion and oxidation. Hermetic ALD coating works efficiently even against moisture and gaseous sulfur in polluted atmosphere. Due to its nanometer-scale thickness, the ALD film has no effect on the PCBA functionality, mass or dimensions and it allows reworking of the PCBA.

Tin whisker formation and corrosion are particularly fatal in several high reliability electronics applications such as data centers, space, aviation, military, medical and industrial control systems. Picosun’s revolutionary ALD encapsulation method offers now safety improvement, product lifetime lengthening, and even long-term cost savings to these manufacturers. Fast, cost-efficient processing of large amounts of PCBAs can be realized in PICOSUN™ P-1000 and P-300B high volume batch ALD systems with production-proven, industry-optimized processes.

“We are happy to announce these groundbreaking results obtained with our ALD encapsulants in protection of specialty electronics. This is a new, potentially huge market for ALD. There has already been lots of interest towards our turn-key coating solutions for large scale PCBA protection from the corresponding industries. This shows again the versatility of ALD and its power to disrupt near all fields of today’s industrial manufacturing”, says Dr. Jani Kivioja, CTO of Picosun Group.

↧

↧

Picosun’s ALD yttria eliminates corrosion in demanding applications

ESPOO, Finland, 25th February 2019 – Picosun Group, a leading supplier of ALD (Atomic Layer Deposition) thin film coating solutions for global industries, has developed an excellent quality ALD yttria process for corrosion protection in harsh environments.

Yttria, aka yttrium oxide, Y2O3, is extremely hard, dense, and mechanically strong material which has excellent chemical and erosion resistance and very high melting point. These characteristics make it ideal for protective coatings in applications where operating conditions are extreme. Some examples of these applications are various semiconductor production equipment and metal production. Y2O3 also finds uses as a high-k gate dielectric in novel microelectronics such as carbon-based components, thin film transistors, and germanium-metal-oxide semiconductors.

Yttria, aka yttrium oxide, Y2O3, is extremely hard, dense, and mechanically strong material which has excellent chemical and erosion resistance and very high melting point. These characteristics make it ideal for protective coatings in applications where operating conditions are extreme. Some examples of these applications are various semiconductor production equipment and metal production. Y2O3 also finds uses as a high-k gate dielectric in novel microelectronics such as carbon-based components, thin film transistors, and germanium-metal-oxide semiconductors.

A street in Sweden close to the Ytterby mine, famous for having the single richest source of elemental discoveries in the world; the chemical elements Yttrium (Y), Ytterbium (Yt), Erbium (Er) and Terbium (Tb) are all named after Ytterby (photo from Miras Miarakel LINK)

Yttrium oxide coatings are typically produced with physical vapor deposition, electron beam evaporation, or sputtering methods, but ALD offers several advantages over these techniques. ALD-manufactured yttria films are intrinsically pinhole-free, extremely dense, ultra-thin, and highly uniform, and they cover conformally even the smallest nanoscale details, voids, crooks, and steps on the surface. Achieving these properties with a fraction of film thickness compared to traditional methods saves costs and materials. As the ALD process is based on spontaneous surface chemical reactions between gaseous reactants, it is gentle to the coated surface and can be applied at moderate temperatures, if needed. Cost-efficient, high throughput production of yttrium oxide coatings can be realized in Picosun’s industry-proven PICOSUN™ P-1000 and P-300B ALD equipment (*).

“Our high volume production ALD machinery such as PICOSUN™ P-1000 and P-300B reactors has been a huge success since their launch. With this equipment we have been able to take ALD to totally new application areas in e.g. surface protection and functionalization of various mechanical components, anti-tarnish and decorative coatings for coins and watch parts, and production of biocompatible coatings for medical devices. Now, our superb quality yttria process, upscaled to production in our high volume reactors, enables revolutionary ALD solutions in industries where durable and reliable surface protection against extreme conditions is needed,” states Dr. Jani Kivioja, CTO of the Picosun Group.

“Our high volume production ALD machinery such as PICOSUN™ P-1000 and P-300B reactors has been a huge success since their launch. With this equipment we have been able to take ALD to totally new application areas in e.g. surface protection and functionalization of various mechanical components, anti-tarnish and decorative coatings for coins and watch parts, and production of biocompatible coatings for medical devices. Now, our superb quality yttria process, upscaled to production in our high volume reactors, enables revolutionary ALD solutions in industries where durable and reliable surface protection against extreme conditions is needed,” states Dr. Jani Kivioja, CTO of the Picosun Group.

↧

The hardest, thinnest, most wear-resistant coatings yet by PEALD titanium and vanadium nitrides

[Lehigh University, Story by Christine Fennessy, shortened] In August 2018, the National Science Foundation (NSF) granted Strandwitz, an assistant professor of materials science and engineering, and Krick, an assistant professor of mechanical engineering and mechanics, a Grant Opportunities for Academic Liaison with Industry (GOALI) award to work with an industry partner to study what exactly makes these nitride films so good.

Low temps, conformality, and precision yield a diamond-like toughness

Titanium and vanadium nitride films are already known to be extremely hard and wear resistant. Traditionally, they’re grown by sputtering, pulsed laser deposition, or chemical vapor deposition methods. In a first, the group’s collaborators at Veeco/CNT grew their nitride films using plasma-enhanced atomic layer deposition, or PE-ALD. Veeco/CNT is a leading supplier of ALD systems based in Waltham, Massachusetts.“In atomic layer deposition, you’re building one layer of atoms at a time,” says Strandwitz. “It’s a technique that’s already used in microelectronics, like on those in your phone, where you might need a film that is exactly three nanometers thick. If the film is four, or two, nanometers thick, your transistor switch won’t work. And you have a few billion transistors in your phone.”

Source: Lehigh University (LINK)

↧

Welcome to Berlin for the biggest ALD Exhibition in Germany since ALD2012 in Dresden!

Welcome to Berlin for the biggest ALD Exhibition in Germany since ALD2012 in Dresden!

ALD for Industry – 3rd Workshop and Tutorial, 19-20 March 2018 in Berlin LINK

Atomic Layer Deposition (ALD) is used to deposit ultraconformal thin films with sub-nm film thickness control. The method is unique in the sense that it employs sequential self-limiting surface reactions for growth in the monolayer thickness regime. Today, ALD is a key technology in leading edge semiconductor technology and the field of application in other leading-edge industries is increasing rapidly. According to market estimates the equipment market alone is currently at an annual revenue of US$ 1.5-1.7 billion (2017) and it is expected to double in the next 4-5 years.

In a European context ALD was invented independently twice in Europe (Russia & Finland) and since the last 15 years Germany has grown to become one of the strongest European markets for ALD in R&D, chemicals, equipment and end users.

The Event will focus on the current markets for ALD and addresses the applications in semiconductor industry, MEMS & Sensors, Battery Technology, Medical, Display, Lightning, Barriers and Photovoltaics.

ALD for Industry – 3rd Workshop and Tutorial, 19-20 March 2018 in Berlin LINK

A topical workshop with focus on industrialization and commercialization of ALD for current and emerging markets

Atomic Layer Deposition (ALD) is used to deposit ultraconformal thin films with sub-nm film thickness control. The method is unique in the sense that it employs sequential self-limiting surface reactions for growth in the monolayer thickness regime. Today, ALD is a key technology in leading edge semiconductor technology and the field of application in other leading-edge industries is increasing rapidly. According to market estimates the equipment market alone is currently at an annual revenue of US$ 1.5-1.7 billion (2017) and it is expected to double in the next 4-5 years.

In a European context ALD was invented independently twice in Europe (Russia & Finland) and since the last 15 years Germany has grown to become one of the strongest European markets for ALD in R&D, chemicals, equipment and end users.

The Event will focus on the current markets for ALD and addresses the applications in semiconductor industry, MEMS & Sensors, Battery Technology, Medical, Display, Lightning, Barriers and Photovoltaics.

↧

Applied Materials - Moore’s Law and the Shift from Near-Memory to In-Memory Compute

Beyond Von Neumann: Moore’s Law and the Shift from Near-Memory to In-Memory Compute

by David Thompson

Feb 27, 2019

In reflecting a little bit on my last blog, it probably would have been good to do a little bit of explaining around what Von Neumann computing is, before discussing what’s beyond it. However, a bit of background on Moore’s Law is in order first.

by David Thompson

Feb 27, 2019

In reflecting a little bit on my last blog, it probably would have been good to do a little bit of explaining around what Von Neumann computing is, before discussing what’s beyond it. However, a bit of background on Moore’s Law is in order first.

↧

↧

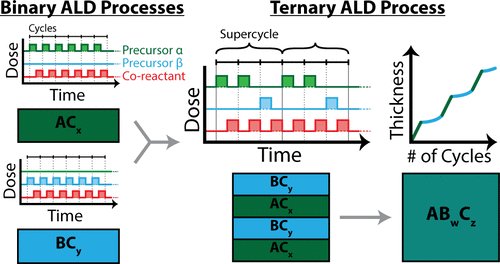

Synthesis of Doped, Ternary, and Quaternary Materials by ALD

A review by Adriaan J. M. Mackus andthe Bent Group at Stanford "Synthesis of Doped, Ternary, and Quaternary Materials by Atomic Layer Deposition"LINK

Picture from Twitter (https://twitter.com/ChemMater/status/1103368831337000960https://twitter.com/ChemMater/status/1103368831337000960https://twitter.com/ChemMater/status/1103368831337000960https://twitter.com/ChemMater/status/1103368831337000960https://twitter.com/ChemMater/status/1103368831337hts://twitter.com/ChemMater/status/1103368831337000960)

↧

Achtung High-k - Novel High-k Workshop 2019 at NaMLab

High k Workshop 2019

NaMLab invites to the Novel High-k Application Workshop on June 11th and 12th, 2019. New challenges offered by the application of high-k dielectric materials in micro– and nanoelectronics were discussed by more than 90 participants from industry, research institutes and universities.In this series of annual workshops NaMLab has created a stimulating platform for application-oriented scientists to exchange ideas and discuss latest experimental results on MIM-capacitors, process technology, leakage & reliability as well as characterization of high-k dielectrics integrated in silicon based micro– and nanoelectronics. The ferroelectric properties of doped HfO2 and ZrO2 were discovered more than 10 years ago. On the second day of the workshop, root causes for the formation of this so far unknown phase will be discussed together with the application of these films.

For more information: LINK

↧

Article 2

Western Digital and Toshiba have developed a 128-layer 3D NAND die with TLC (3bits/cell) cell formatting and 512Gbit capacity.Acoording to etimates and modelling WD-Toshiba has the industry’s highest NAND density and models the suppliers at an 85 per cent wafer yield - thanks Terry Francis for sharing.

↧

Longi rejects Hanwha Q Cells allegations and provides details on patent issue

[PV Magazine] The Chinese monocrystalline module maker said it had not been notified of the legal action by its Korean rival. Longi claimed there is considerable uncertainty over the validity of the patents at the root of the lawsuits, which the Chinese defendant says relate to ALD technology. Longi says it uses PECVD technology for cell production.

Hanwha on Tuesday said it had filed lawsuits with the U.S. International Trade Commission (US ITC) and the U.S. District Court in Delaware claiming Longi, Jinko and Norwegian module manufacturer REC infringed its U.S. Patent No. 9,893,215, by using Hanwha’s passivation technology to increase the efficiency and performance of their solar cells.

“The patent family used by Hanwha Q Cells in the complaint is acquired through multiple transfers and transactions from other research institutes; [which] act as a co-owner to the patents,” Longi said. “Currently, several opposition procedures against the patents have been filed, at least in Europe, and there is considerable uncertainty with regards to the validity of the patent rights.”

Source: PV Magazine LINK

↧

↧

What Will Come After V‐NAND—Vertical Resistive Switching Memory?

Here is a hot paper from Hwang in Advanced Materials on what may come after V-NAND/3DNAND Flash meory architecture. In the case of Vertical ReRAM we can assume that there are numerous opportunities for funky ALD materials and processes!

What Will Come After V‐NAND—Vertical Resistive Switching Memory?

Kyung Jean Yoon, Yumin Kim, Cheol Seong Hwang

Version of Record online:28 February 2019

https://doi.org/10.1002/aelm.201800914

Kyung Jean Yoon, Yumin Kim, Cheol Seong Hwang

Version of Record online:28 February 2019

https://doi.org/10.1002/aelm.201800914

Pathways to overcome the scaling limitation of vertical NAND flash memory (V‐NAND), the present market leading nonvolatile memory, providing new materials and array structure suggestions, are provided. Specifically, the favorable aspects of a vertical resistive random access memory (V‐ReRAM) structure, such as areal density and decoding schemes, are highlighted in comparison with the commercialized nonvolatile memories: 3D‐Crosspoint and V‐NAND.

↧

RASIRC Presents Process Control ‘Ins and Outs’ for Optimized Mass Delivery

New data reveals optimization opportunities in throughput and precursor utilization

San Diego, Calif – March 14, 2019 – Dynamic gas generation leader RASIRC will present new data on process optimization for low temperature ALD at the upcoming ALD for Industry 2019 conference. The presentation entitled “Optimization of Delivered Mass from Low Vapor Pressure Precursors through Process Control” is scheduled for 13:50 on Wednesday March 20 as part of the ALD Precursor Development session. RASIRC is a Gold Sponsor and exhibitor at the event held March 19-20 in Berlin, Germany.“Controlled delivery of low vapor pressure liquids is challenging, but necessary, for low temperature thermal ALD,” said Jeffrey Spiegelman, President and Founder. “Our data shows that both throughput and precursor utilization can be optimized through precise control of the many variables involved in the process, resulting in consistent and regulated vapor.”

ALD for Industry is an annual event sponsored by the European Society for Thin Films (EFDS). New materials and complex 3D structures now common in many semiconductor and display devices require deposition at the atomic layer and at low temperature. RASIRC is a leader in controlled delivery of highly reactive oxidants and nitrides for low temperature thermal ALD.

Spiegelman will present findings from automated test programs that simulated process recipes in common ALD conditions. Data collected quantified mass flowrates at different process conditions. Spiegelman will also be available to answer questions and discuss findings at the RASIRC exhibit.

About RASIRC Products

BRUTE® Peroxide is a novel oxidant that improves passivation and nucleation density at film interfaces when compared to other oxidants. Surface functionalization is denser and initiation is faster using this anhydrous hydrogen peroxide gas compared with alternatives. This high reactivity allows for less chemistry use and higher throughput due to shorter required purge times.

BRUTE® Hydrazine enables conformal growth with low wet-etch-rates for SiN. BRUTE® Hydrazine gas is virtually water free and has a relatively high flash point for safer handling. Highly reactive, BRUTE Hydrazine creates uniform nitride deposition for advanced materials at low temperature.

RASIRC’s Peroxidizer® provides high volumes of reactive H2O2/H2O mixtures for high throughput ALD. This reactive gas generator is ideal for roll-to-roll ALD coatings that require high speed deposition at reduced temperatures.

Additional RASIRC products include the RainMaker Humidification System (RHS) and the Hydrogen Peroxide Steamer (HPS). The RHS generates water vapor for oxidation applications and the HPS provides surface cleaning, preconditioning, wet thermal oxidation and residual carbon removal.

About RASIRC

RASIRC specializes in products that generate and deliver gas to fabrication processes. Each unit is a dynamic gas plant in a box — converting common liquid chemistries into safer and reliable gas flow for most processes. RASIRC technology delivers water vapor, hydrogen peroxide gas and hydrazine gas in controlled, repeatable concentrations. RASIRC gas delivery systems, humidifiers, and closed loop humidification systems are critical for many applications in semiconductor, photovoltaic, pharmaceutical, medical, biological, fuel cell, and power industries. Call 858-259-1220, email info@rasirc.com or visit http://www.rasirc.com.

ALD for Industry is an annual event sponsored by the European Society for Thin Films (EFDS). New materials and complex 3D structures now common in many semiconductor and display devices require deposition at the atomic layer and at low temperature. RASIRC is a leader in controlled delivery of highly reactive oxidants and nitrides for low temperature thermal ALD.

Spiegelman will present findings from automated test programs that simulated process recipes in common ALD conditions. Data collected quantified mass flowrates at different process conditions. Spiegelman will also be available to answer questions and discuss findings at the RASIRC exhibit.

About RASIRC Products

BRUTE® Peroxide is a novel oxidant that improves passivation and nucleation density at film interfaces when compared to other oxidants. Surface functionalization is denser and initiation is faster using this anhydrous hydrogen peroxide gas compared with alternatives. This high reactivity allows for less chemistry use and higher throughput due to shorter required purge times.

BRUTE® Hydrazine enables conformal growth with low wet-etch-rates for SiN. BRUTE® Hydrazine gas is virtually water free and has a relatively high flash point for safer handling. Highly reactive, BRUTE Hydrazine creates uniform nitride deposition for advanced materials at low temperature.

RASIRC’s Peroxidizer® provides high volumes of reactive H2O2/H2O mixtures for high throughput ALD. This reactive gas generator is ideal for roll-to-roll ALD coatings that require high speed deposition at reduced temperatures.

Additional RASIRC products include the RainMaker Humidification System (RHS) and the Hydrogen Peroxide Steamer (HPS). The RHS generates water vapor for oxidation applications and the HPS provides surface cleaning, preconditioning, wet thermal oxidation and residual carbon removal.

About RASIRC

RASIRC specializes in products that generate and deliver gas to fabrication processes. Each unit is a dynamic gas plant in a box — converting common liquid chemistries into safer and reliable gas flow for most processes. RASIRC technology delivers water vapor, hydrogen peroxide gas and hydrazine gas in controlled, repeatable concentrations. RASIRC gas delivery systems, humidifiers, and closed loop humidification systems are critical for many applications in semiconductor, photovoltaic, pharmaceutical, medical, biological, fuel cell, and power industries. Call 858-259-1220, email info@rasirc.com or visit http://www.rasirc.com.

↧

Review—Cobalt Thin Films: Trends in Processing Technologies and Emerging Applications

Here is a fantastic revie on Cobalt ALD and CVD from SUNY Polytechnic Institute and Gelest and it is fee to download - Thanks for sharing this one Henrik Pedersen!

Editors' Choice—Review—Cobalt Thin Films: Trends in Processing Technologies and Emerging Applications

Alain E. Kaloyeros, Youlin Pan, Jonathan Goff and Barry Arkles

Alain E. Kaloyeros, Youlin Pan, Jonathan Goff and Barry Arkles

ECS Journal of Solid State Science and Technology, 8 (2) P119-P152 (2019) (LINK)

Cobalt metallic films are the subject of an ever-expanding academic and industrial interest for incorporation into a multitude of new technological applications. This report reviews the state-of-the art chemistry and deposition techniques for cobalt thin films, highlighting innovations in cobalt metal-organic chemical vapor deposition (MOCVD), plasma and thermal atomic layer deposition (ALD), as well as pulsed MOCVD technologies, and focusing on cobalt source precursors, thin and ultrathin film growth processes, and the resulting effects on film composition, resistivity and other pertinent properties.

Cobalt metallic films are the subject of an ever-expanding academic and industrial interest for incorporation into a multitude of new technological applications. This report reviews the state-of-the art chemistry and deposition techniques for cobalt thin films, highlighting innovations in cobalt metal-organic chemical vapor deposition (MOCVD), plasma and thermal atomic layer deposition (ALD), as well as pulsed MOCVD technologies, and focusing on cobalt source precursors, thin and ultrathin film growth processes, and the resulting effects on film composition, resistivity and other pertinent properties.

Open access article distributed under the terms of the Creative Commons Attribution 4.0 License (CC BY, http://creativecommons.org/licenses/by/4.0/)

↧

Critical Materials Conference - Early Bird Reg Ending 4th Annual CMC Conference April 25-26 in Saratoga Springs, New York

ALD Folks - this year we have a good number of ALD related talks : Air Liquide, Schrödinger, TECHCET, Fraunhofer, Applied Materials, Tokyo Electron and more

↧

↧

Meyer Burger announces record HJT cells with efficiencies over 24%

At the PV CellTech conference in Penang, Malaysia from 12 – 13 March 2019, Meyer Burger CTO, Dr Gunter Erfurt, will speak to two leading technology topics – Heterojunction and Passivated Contacts.

Dr Erfurt was also asked to speak on passivated contact solar cells (also known as TOPCon or monoPoly®) and what is required for this technology to become a mainstream offering in the PV industry during the keynote session at PV CellTech. Today the prevailing mainstream technology in the photovoltaic market is PERC (Passivated Emitter Rear Contact) cell coating technology. Current PERC solar cells achieve efficiency levels of between 21% and 22% but there are significant technology limitations, which affect the potential for further increases in PERC cell efficiency. Passivated contact technology can offer an evolutionary upgrade to existing PERC mass production capacities, taking them to efficiency levels around 23%.

The heterojunction technology combines the advantages of crystalline silicon solar cells and thin film technologies enabling solar cell to reach higher degrees of efficiency at a lower cost of production (Youtube).

For the past two years, Meyer Burger has been developing a platform for the industrialized manufacture of solar cells with passivated contact technology for both n- and p-type wafers. In trials with customers, the CAiA® platform has already produced cells with efficiencies slightly above 23% and the first lab machine has already been sold to a strategic customer and technology partner, with initial installations planned by midyear. The CAiA® ideally complements Meyer Burger’s industry leading MAiA® and FABiA® cell coating portfolio with both current as well as new customers benefitting from a combination of the CAiA® together with either the MAiA® or FABiA® as the optimal solution for the manufacture of passivated contact cells. Meyer Burger’s SWCT™ module technology is the ideal solution not only for HJT modules but also for the most cost-effective production of solar modules with passivated contact cells.

Recently solar module manufacturer, Hanwha Q Cells, submitted a patent infringement claim against several Asian solar module producers for the use of Atomic Layer Deposition (ALD) passivation technology. Meyer Burger’s MAiA® and FABiA® cell coating platforms use the company’s proprietary Plasma Enhanced Chemical Vapor Deposition (PECVD) passivation technology, which is the leading alternative technology to ALD and thus not in the scope of the patent infringement claim by Hanwha Q Cells.

Heterojunction – Meyer Burger’s flagship technology

At PV CellTech 2019, international PV industry leaders will discuss key issues driving the development of solar cell production in the coming years. Meyer Burger CTO, Dr Gunter Erfurt, has been invited to present to a high-level session focusing on Heterojunction (HJT) cell expansion and its potential as a breakthrough technology for multi-gigawatt mass production in 2019. With its focus on the development of industrialized high efficiency Heterojunction manufacturing solutions, Meyer Burger has already achieved HJT cells with recent record efficiencies of over 24.2% on its standardized HJT equipment. A technology roadmap for HJT cells with efficiencies towards 25% is already in place at Meyer Burger. During his presentation, Dr Erfurt will include an update on Meyer Burger’s successful SWCT™ cell connection technology for which over 1 GW has already been sold.Dr Erfurt was also asked to speak on passivated contact solar cells (also known as TOPCon or monoPoly®) and what is required for this technology to become a mainstream offering in the PV industry during the keynote session at PV CellTech. Today the prevailing mainstream technology in the photovoltaic market is PERC (Passivated Emitter Rear Contact) cell coating technology. Current PERC solar cells achieve efficiency levels of between 21% and 22% but there are significant technology limitations, which affect the potential for further increases in PERC cell efficiency. Passivated contact technology can offer an evolutionary upgrade to existing PERC mass production capacities, taking them to efficiency levels around 23%.

The heterojunction technology combines the advantages of crystalline silicon solar cells and thin film technologies enabling solar cell to reach higher degrees of efficiency at a lower cost of production (Youtube).

CAiA® – Meyer Burger’s new platform to drive TopCon industrialization

For the past two years, Meyer Burger has been developing a platform for the industrialized manufacture of solar cells with passivated contact technology for both n- and p-type wafers. In trials with customers, the CAiA® platform has already produced cells with efficiencies slightly above 23% and the first lab machine has already been sold to a strategic customer and technology partner, with initial installations planned by midyear. The CAiA® ideally complements Meyer Burger’s industry leading MAiA® and FABiA® cell coating portfolio with both current as well as new customers benefitting from a combination of the CAiA® together with either the MAiA® or FABiA® as the optimal solution for the manufacture of passivated contact cells. Meyer Burger’s SWCT™ module technology is the ideal solution not only for HJT modules but also for the most cost-effective production of solar modules with passivated contact cells.

Patent infringement claim by Hanwha Q Cells

Recently solar module manufacturer, Hanwha Q Cells, submitted a patent infringement claim against several Asian solar module producers for the use of Atomic Layer Deposition (ALD) passivation technology. Meyer Burger’s MAiA® and FABiA® cell coating platforms use the company’s proprietary Plasma Enhanced Chemical Vapor Deposition (PECVD) passivation technology, which is the leading alternative technology to ALD and thus not in the scope of the patent infringement claim by Hanwha Q Cells.

↧

Atomic Layer Deposition System to Drive Renewable Energy Innovation

March 14, 2019 : The Sharp Group at Walter Schottky Institute Adopts Veeco’s Fiji F200 ALD System for Advancement of Functional Semiconductors and Catalysts

PLAINVIEW, New York — Veeco Instruments Inc. today announced that The Sharp Group at Germany’s Walter Schottky Institute (WSI) has taken delivery of Veeco’s Fiji® F200™ Plasma-Enhanced Atomic Layer Deposition (PE-ALD) system. As a leader in the fabrication and characterization of functional semiconductors and catalysts, The Sharp Group will leverage the Fiji system as an integral part of its discovery and material development efforts for applications in renewable energy conservation.

PLAINVIEW, New York — Veeco Instruments Inc. today announced that The Sharp Group at Germany’s Walter Schottky Institute (WSI) has taken delivery of Veeco’s Fiji® F200™ Plasma-Enhanced Atomic Layer Deposition (PE-ALD) system. As a leader in the fabrication and characterization of functional semiconductors and catalysts, The Sharp Group will leverage the Fiji system as an integral part of its discovery and material development efforts for applications in renewable energy conservation.

“The development of renewable energy solutions calls for increasingly complex thin films and nanostructures, and to advance our work in this area requires an approach that is adaptable for a wide range of deposition techniques,” said Professor Ian Sharp, Ph.D., head of The Sharp Group at WSI. “Veeco not only has the requisite technical expertise but also offers invaluable scientific support. With the Fiji ALD system purchase, we’ve made a valuable and long-lasting partnership.”

The Fiji system is a flexible, single-wafer ALD reactor designed to deliver best-in-class performance for both thermal and plasma-enhanced ALD processes. Its demonstrated ability to precisely control the composition, structure and phase of multicomponent materials is critical to The Sharp Group to accelerate energy conversion mechanisms and direct function properties. Veeco has installed over 550 ALD systems, more than any other R&D supplier, at leading universities and customer facilities worldwide. Backed by Veeco’s global service team, the company’s ALD portfolio includes the Fiji, Savannah®, Phoenix® andFirebird™ systems to support a full range of R&D and production applications.

“New materials engineering challenges and applications arise every day, making Veeco’s ALD platforms ideal for those seeking the most versatile plasma-enhanced systems and thermal tools available,” added Ganesh Sundaram, Ph.D., vice president of applied technology for Veeco’s ALD group. “We anticipate an extremely productive collaboration with Professor Sharp and his team at WSI as they develop new technologies for sustainability and energy innovation.”

Veeco will exhibit and present at the EFDS ALD for Industry 2019 conference, March 19-20 in Berlin, Germany. Dr. Ganesh Sundaram’s workshop presentation, “ALD Use for Decorative Applications,” is scheduled for 11:10 a.m. CET on Wednesday, March 20, 2019.

The Fiji system is a flexible, single-wafer ALD reactor designed to deliver best-in-class performance for both thermal and plasma-enhanced ALD processes. Its demonstrated ability to precisely control the composition, structure and phase of multicomponent materials is critical to The Sharp Group to accelerate energy conversion mechanisms and direct function properties. Veeco has installed over 550 ALD systems, more than any other R&D supplier, at leading universities and customer facilities worldwide. Backed by Veeco’s global service team, the company’s ALD portfolio includes the Fiji, Savannah®, Phoenix® andFirebird™ systems to support a full range of R&D and production applications.

“New materials engineering challenges and applications arise every day, making Veeco’s ALD platforms ideal for those seeking the most versatile plasma-enhanced systems and thermal tools available,” added Ganesh Sundaram, Ph.D., vice president of applied technology for Veeco’s ALD group. “We anticipate an extremely productive collaboration with Professor Sharp and his team at WSI as they develop new technologies for sustainability and energy innovation.”

Veeco will exhibit and present at the EFDS ALD for Industry 2019 conference, March 19-20 in Berlin, Germany. Dr. Ganesh Sundaram’s workshop presentation, “ALD Use for Decorative Applications,” is scheduled for 11:10 a.m. CET on Wednesday, March 20, 2019.

↧

Edwards announces the new iXH Mk2 Series

BURGESS HILL, England--(BUSINESS WIRE)--Mar 14, 2019--Edwards announces the new iXH Mk2 Series – a high efficiency, low-power, ultra harsh duty dry pump that meets today’s semiconductor process requirements and addresses tomorrow’s emerging application challenges in the semiconductor, display, LED and solar PV manufacturing processes. Edwards will showcase the new iXH Mk2 solution at SEMICON ® China, taking place March 20-22, SNIEC, Shanghai (booth 1309 FPD CHINA).

“The new iXH Mk2 dry pump provides an even longer service life than previous generations for the harshest of processes. It can also provide significant improvements in power efficiency,” said Al Brightman, Sr. Product Manager, Edwards. “Leveraging 100 years of technology innovation, we have ‘reset the bar’ for harsh process capability, reliability and low cost-of-ownership. The iXH reduces the environmental impact of some of the harshest processes used in semiconductor manufacturing.”

Stop by the booth to learn how the iXH Mk2 solves emerging process challenges in high-k, low-k, SACVD, LPCVD, ALD, TCO, GaN and EPI. Further information about Edwards can be found at www.edwardsvacuum.com.

Stop by the booth to learn how the iXH Mk2 solves emerging process challenges in high-k, low-k, SACVD, LPCVD, ALD, TCO, GaN and EPI. Further information about Edwards can be found at www.edwardsvacuum.com.

↧